Anilox

Protection System

The first and only Anilox cleaning system that guarantees an increase in printing performance and roll life, without the use of chemicals.

That’s how:

TESTED

TECHNOLOGY

Designed and developed in collaboration with the leading manufacturers of Anilox, Bicarjet’s technology amplifies the efficacy of bicarbonate ensuring highest cleaning performances without risk of wear.

ROLLER

PROTECTION

As demonstrated by the University of Trento and from direct experiences, bicarbonate keeps the surface of the rollers intact and, unlike other cleaning methods, it preserves their long performances, improving their printing efficiency.

STAFF

SAFTEY

Anilox Protection System guarantees the total safety of the operator who, coming into contact only with low pressure food grade baking soda, does not take any health risks.

WITHOUT CHEMISTRY,

DOWN WITH WASTE

Thanks to the specific recirculation technology and to the use of Meltron Anilox only, an

exclusive saline compound based of bicarbonate, the production of cleaning waste is significantly reduced.

DEEPER CLEANING

Meltron Anilox has a granulometry designed to treat effectively even the latest generation rollers, being able to penetrate even into the smallest cells.

INTACT ROLLS

The bicarbonate micro particles, shoot on the rollers, disintegrate in the impact taking away the dirt without scratching the surfaces.

Designed and patented by our research and development department, Meltron Anilox represents the bicarbonate-based cleaning agent more secure and natural on the market.

That's why:

EFFICIENT

- Performance in cleaning

- Reliable over time

- High printing performances

CHEAP

- Low investment

- Low operating costs

- Reduced maintenance

SURE

- Use food-grade baking soda

- Low working pressure

- Without chemicals

FLEXIBLE

- Tailor-made commercial solutions

- Equipment rental service

- Continuous assistance

Cleaning for flexographic printing rolls:

le macchine

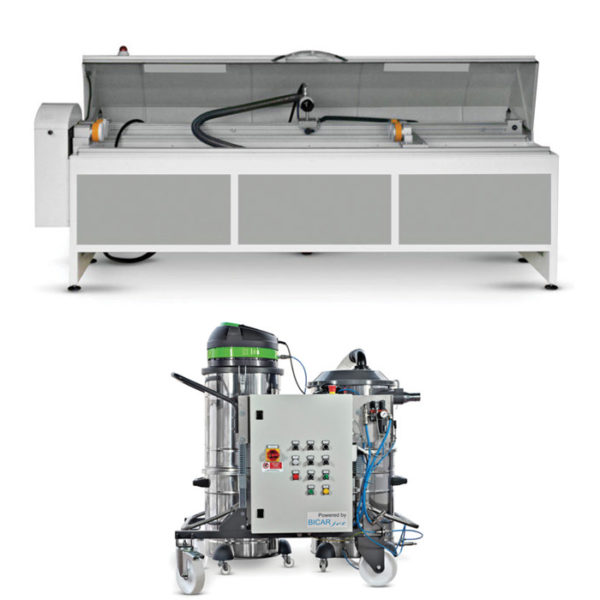

The solution for automated dry cleaning of the rollers once disassembled from the production machine.…

When the disassembly of the roller from the production line is difficult or impossible, dry…

Storage system Revolver is the system designed for the transport and storage of 9 to…

Our vertical cabin is the ideal solution for dry and automatic cleaning of all sleeves.…

Contact us!

- Via Nona Strada, 4, 35129 Padova PD

- +39 049 780 8036

- info@bicarjet.com