Molds for pharmaceutical rubber:

the definitive cleaning system

The cleaning of the molds dedicated to the production of rubber items for the pharmaceutical sector must be integrated with the specific needs and high standards of the market.

Safety, biocompatibility, absence of pollutants and process certification are the key words and key elements for choosing the most suitable cleaning system.

In this sector, Bicarjet has gained significant experience, allowing the major world producers to achieve important goals without including any risk factors in the process.

The main areas in which an adequate cleaning of the molds in the pharmaceutical sector is required are: production of o-rings or special sealing gaskets, production of syringe plungers or production of case stopper.

The main challenges in cleaning the molds in the pharmaceutical sector are: the removal of molding and release agents, the biocompatibility of the cleaning process with respect to the final product, the absence of cross-contamination and safety for operators, for the process and for the artifacts to be treated.

The BicarJet cleaning process, specifically designed for the pharmaceutical market, makes it possible to clean the latest generation molds and compounds, such as chromobutulic and bromobutyl, NBR, HNBR, VITON, and fluoroelastomers with the utmost accuracy.

Increased productivity

Our mould cleaning system for pharmaceutical rubber production guarantees a marked increase in processing throughput.

Usable on hot mould

The entire system can be used without any criticality even on the still hot mould and is easily automated.

NOT ABRASIVE

The BicarJet system does not damage the surface of the mould, it is also effective in undercuts and on grooves up to 40 mm deep.

SAFE FOR THE OPERATOR

The use of low pressure, foodgrade bicarbonate and the total absence of chemicals makes the BicarJet solution the safest for the operator.

EASY TO USE

All our solutions are built in Italy keeping in mind the ease of use for the operator.

DEEPER CLEANING

The special bicarbonate used has a granulometry designed to treat even the molds with smaller cavities.

INTACT MOLDS

The micro bicarbonate particles, fired on the molds, disintegrate in the impact taking away the dirt with them, without scratching the surfaces.

Bicarjet has designed a process that combines the strength of baking soda with a dedicated technology to guarantee maximum efficiency and safety for treated surfaces and for operators.

That's why:

EFFICIENT

- Performance in cleaning

- Reliable over time

- Does not damage the molds

CHEAP

- Low investment

- Low operating costs

- Reduced maintenance

SURE

- Use food-grade baking soda

- Low working pressure

- Without chemicals

FLEXIBLE

- Tailor-made commercial solutions

- Equipment rental service

- Continuous assistance

Cleaning moulds for pharmaceutical rubber:

le macchine

We create customized cleaning and surface treatment solutions. We support the customer in all phases…

We create customized mold cleaning and surface treatment solutions for manufacturers of rubber articles for…

Ecoloop is BicarJet’s innovative recirculation solution: compared to traditional systems, it uses a supersaturated mixture…

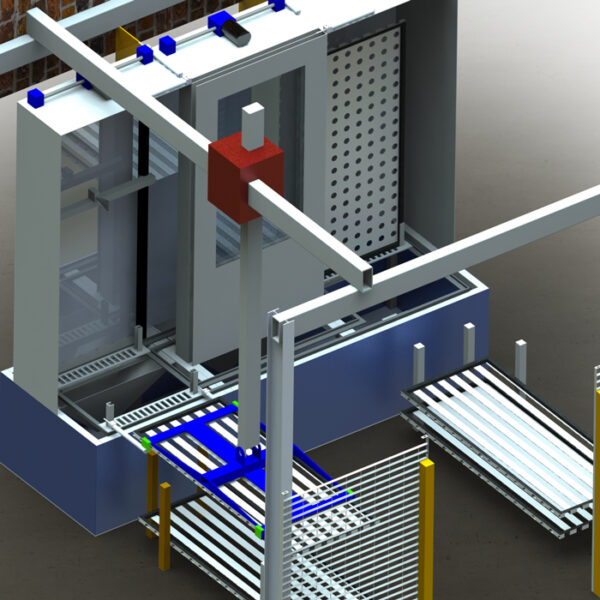

The MJ1000 cabin is the ideal solution for cleaning molds in the pharmaceutical sector, dedicated…

The MJ900 cabin is the ideal solution for mold cleaning in the pharmaceutical sector, dedicated…

The MK1500 cabin is the ideal solution for mold cleaning in the pharmaceutical sector, dedicated…

Contact us!

- Via Nona Strada, 4, 35129 Padova PD

- +39 049 780 8036

- info@bicarjet.com