We create customized cleaning and surface treatment solutions.

We support the customer in all phases of creating a customized solution to solve critical issues in the cleaning process, identifying the most performing technology or developing ad hoc projects in relation to the type and size of production pieces to be cleaned and contaminants to be removed.

How does it work?

After an initial analysis, a phase of gathering requirements and drafting of the functional analysis, we move on to the design and implementation phase. A crucial role is played by the pre-test phase to verify the type of Meltron sodium bicarbonate and the most performing technology: dry, wet or mixed and the level of automation required.

We pay great attention to the features of the production environments in which the machine will be installed.

All phases, from the first contact with the customer to the after-sales service, are managed internally to have direct control of every quality aspect. The presence of an internal mechanical workshop also offers the possibility to respond in real time to customer requests.

Innovation and dynamism, experience and know-how in various sectors push us to find new solutions every time, able to satisfy the requests of completely different customers.

MECHANIC INDUSTRY

This particular field of applications covers a wide variety of cases: engines, turbines, gears, clutches: regular or exceptional maintenance is always necessary, that is to clean and degrease entire and complex elements, components, disassembled parts of all sizes. Vehicles of all types: cars, trucks, trains, bulldozers, machinery, production lines, various equipment.

PETROCHEMICAL

The field of application of the surface cleaning solution proposed by BicarJet in these sectors of activity is related to the cleaning and degreasing of industrial production plants and all types of equipment or installations.

For a correct and continuous operation, we have developed solutions for the regular maintenance of tanks, tuber bundles, valves, pumps of different composition: steel, cast iron, stainless steel.

AERONAUTIC

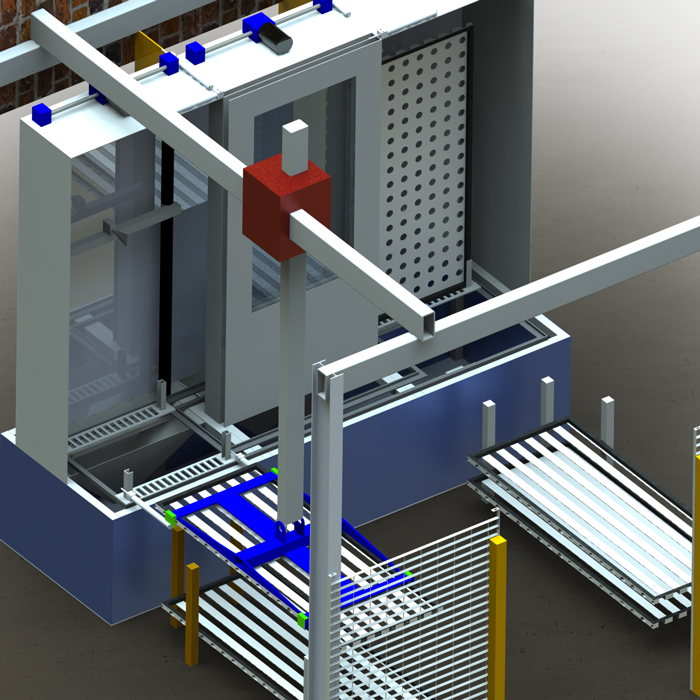

The molds used by the main manufacturers of components for the aeronautical sector are of important dimensions and use highly adherent contaminants. Among the most ambitious projects we have created a fully automated mold cleaning system of more than two meters.

RAILWAY

Cleaning the bodies of train cabins traditionally has a long and dangerous process for operators. The solution we developed allowed to reduce the cleaning time by 75%, while reducing the use of chemistry and increasing safety for operators.

In all these sectors, the cleaning process is a critical factor in increasing the quality of the finished product.

Vuoi rivoluzionere il tuo sistema di pulizia?

Contact us!

- Via Nona Strada, 4, 35129 Padova PD

- +39 049 780 8036

- info@bicarjet.com